Automatic Brick Making Machine 2024?

Automatic brick making machines are advanced brick manufacturing equipment that operate with minimal human intervention. They are designed to automate the process of brick or block production, resulting in high production capacity, consistency in brick quality, and increased efficiency. Here are the key features and components of automatic brick making machines:

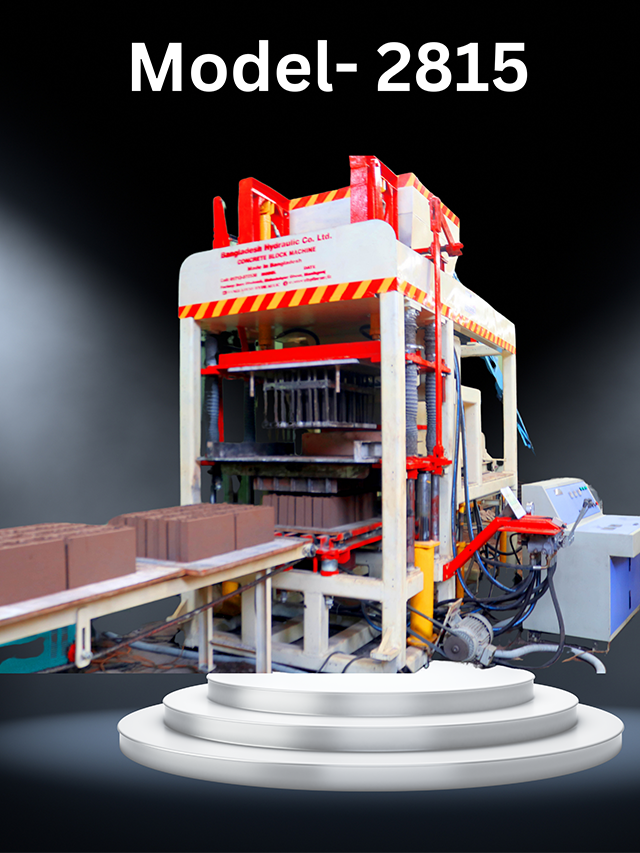

New concrete block machine price in bangladesh BCHBMMC 3515

1. **Feeding System**: Automatic brick making machines typically have a feeding system that loads raw materials, such as cement, sand, aggregate, and water, into the machine’s mixing chamber. The exact proportions are set according to the desired brick specifications.

2. **Mixing Chamber**: The mixing chamber is where the raw materials are combined and mixed thoroughly to form a uniform mixture. This is a crucial step to ensure the strength and consistency of the bricks.

3. **Brick Forming or Molding System**: Automatic machines have a brick forming system that shapes the mixed material into bricks or blocks. This can be done through a hydraulic system or vibration, depending on the machine’s design.

4. **Pressing or Compaction System**: An automatic brick making machine has a pressing or compaction system that applies the necessary pressure to compact the raw material into brick shapes. This results in bricks with consistent density and strength.

5. **Hydraulic System**:

Most automatic brick making machines use a hydraulic system to control various functions, including the application of pressure and the movement of components within the machine. Hydraulic systems ensure precise and uniform compression of the material.

6. **Conveyor Belt or Pallet System**: Once the bricks or blocks are formed, they are transported away from the machine using a conveyor belt or pallet system. This automation simplifies the handling of the finished products.

7. **Cutting System (Optional)**: Some automatic machines include a cutting system that trims the excess material from the top of the bricks or blocks to achieve the desired dimensions.

8. **Control Panel**: Automatic brick making machines are equipped with a control panel that allows operators to set parameters such as brick size, production rate, and other specifications. The control panel also monitors and adjusts the machine’s operations as needed.

9. **Stacking and Packaging (Optional)**: In some cases, automatic machines come with stacking and packaging systems that arrange the finished bricks or blocks into pallets or bundles for easier handling and transportation.

Automatic brick making machines are suitable for large-scale production in brick manufacturing plants. They significantly reduce the labor required for brick production and offer higher production capacity, resulting in cost savings and improved product consistency. These machines are widely used in the construction industry to meet the demand for bricks and blocks in various building projects.

Classifications Of Automatic Brick Making Machine In Bangladesh

Automatic brick making machines in Bangladesh, as in other parts of the world, can be classified based on various criteria, including production capacity, technology, and the types of bricks or blocks they produce. Here are some common classifications of automatic brick making machines in Bangladesh:

block making machine

1. **Production Capacity**:

– **Small-scale Automatic Brick Making Machine**: These machines are designed for lower production capacities, making them suitable for small brick manufacturing businesses and startups.

– **Medium-scale Automatic Brick Making Machine**: Medium-scale machines offer a moderate production capacity and are suitable for established brick manufacturers looking to increase their output.

– **Large-scale Automatic Brick Making Machine**: These machines are equipped for high production capacity and are used by large brick manufacturing facilities and construction companies to meet high demand.

2. **Technology**:

– **Hydraulic Automatic Brick Making Machine**:

Hydraulic technology is used to apply pressure and control various functions of the machine. This technology ensures precise and consistent brick production.

– **Pneumatic Automatic Brick Making Machine**: Pneumatic technology uses compressed air to control certain machine operations. It is less common than hydraulic technology for brick making machines but may be used in some models.

– **Vibration-based Automatic Brick Making Machine**: These machines use vibration to compact the raw materials and form bricks or blocks. They are suitable for specific types of bricks.

3. **Types of Bricks or Blocks Produced**:

– **Solid Brick Making Machine**: These machines produce solid bricks that are used in various construction applications.

– **Hollow Block Making Machine**: Designed for hollow blocks, which are commonly used in construction for their lightweight properties.

– **Interlocking Brick Making Machine**: These machines produce interlocking bricks that can be assembled without the need for mortar or adhesives.

– **Paving Block Making Machine**: Used to manufacture paving blocks, which are often used for walkways, driveways, and other hardscape features.

– **Fly Ash Brick Making Machine**: Designed specifically for producing bricks using fly ash as a raw material, which is environmentally friendly and cost-effective.

4. **Fully Automatic vs. Semi-Automatic**:

– **Fully Automatic Brick Making Machine**: These machines operate with minimal human intervention and are capable of batching, mixing, molding, pressing, and even stacking the finished bricks. They are highly efficient and offer consistent quality.

– **Semi-Automatic Brick Making Machine**: Semi-automatic machines require some manual input, such as loading raw materials, but automate the molding and pressing processes. They provide a balance between automation and manual control.

5. **Mobile vs. Stationary**:

– **Stationary Automatic Brick Making Machine**: Stationary machines are set up in a fixed location and are used for brick production at a specific site.

– **Mobile Automatic Brick Making Machine**: Mobile machines are portable and can be easily transported to different locations for on-site brick production.

The choice of an automatic brick making machine in Bangladesh depends on factors such as the scale of production, the type of bricks or blocks required, available technology, and the budget. Bangladesh has a growing construction industry, and these classifications cater to a wide range of brick production needs in the country.

Auto brick machine price in bangladesh

block machine in bangladesh

Best service

block machine in bangladesh

Block Making Machine

brick machine

Brick Making Machine

Building Material Machine

cheap concrete block making machine

Concrete bricks machine sale

easy install

Factory direct sale

Famous brand

first machinery company in bangladesh

Fly Ash Brick Making Machine

good package

good services

Heavy Duty Equipment

High product quality

high quality

Higher Quality with Competitive Price

hollow block machine price in bangladesh

hollow brick /solid

low freight

low maintenance

Mixing Station

Mobile Block Machine

modular transport

Mould Category

Multi-functional fully automatic block making machine

New concrete bricks machine price

Pallet-Free Block Machine

Pallets Category

Reliable Bricks Machine Supplier In Dhaka

Safe & On Time Delivery

Affordable machine

the trusted machinery company

top-Class Block Machine

Video of Block Machine